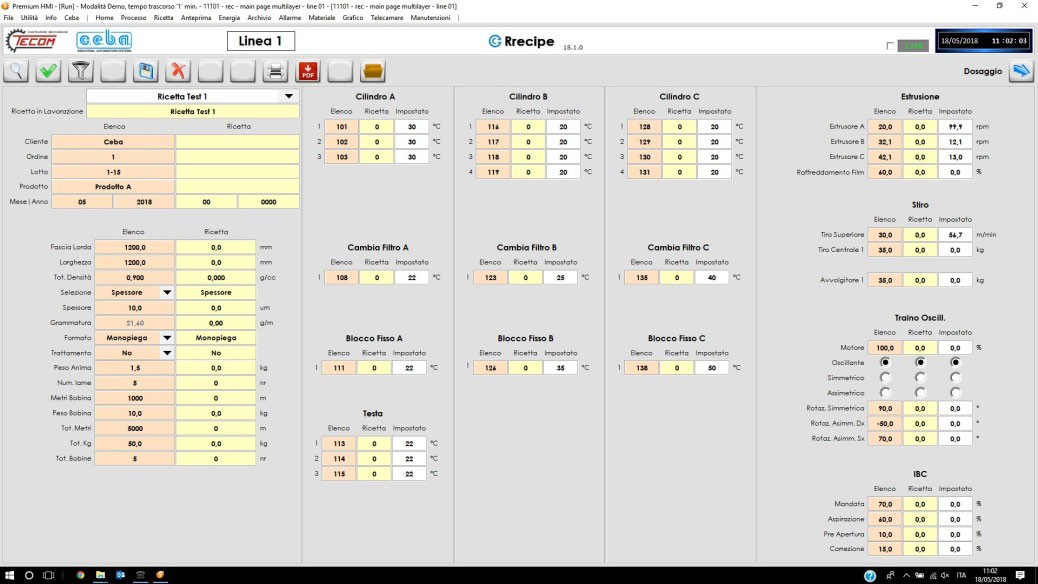

PLATFORM FOR PRODUCTION CONTROL

An indispensable analysis tool for managing the production process on different levels

OPCS is the production control platform developed by C.E.B.A. using the most advanced scada solutions.

OPCS is an indispensable analysis tool for the management of the production process on different levels: from data collection to their processing with the aim of:

- Optimizing production

- Meeting delivery dates

- Manufacturing products of verified quality during the entire production process

- Minimizing costs

- Reducing waste and malfunctions

- Increasing turnover and profits

The software solutions that the OPCs platform makes available to the company to achieve such objectives are:

- Remote recipes

- Production reports

- Energy consumption control

- Process data archiving

- Plant alarms

- Statistical forecast of consumption according to recipes

- Preventive maintenance

- Tele-assistance

- Label printing

- Graphic elaboration of process variables

- Production Efficiency Indicator

- Remote control of correct management performance and process operation

OPCS for high business performance

OPCS: improved interconnection, improved performance

When machines, devices and systems synchronize into a centralized and consistent business system, business performance immediately improves.

Data acquired, stored and interpreted with greater ease and efficiency becomes a valuable and indispensable source of information which allows:

- Preventive maintenance

- Optimization of energy efficiency

- Reduction of plant downtime

- Performance analysis

- Optimization of business processes

Intelligent Industry

They are almost synonyms, or rather, they are strictly interdependent.

In fact, following the dictates and prescriptions of Industry 4.0, we get to the concept of Intelligent Industry (or, for some, smart) that tells of optimized processes, interconnected data, scheduled and remote interventions, predictive maintenance, and safety.

is one of the most suitable tools for this digital journey.

is one of the most suitable tools for this digital journey.

Destination: performance.

Industry 4.0 and smart industry

To access tax benefits

National industry 4.0 plan

Today, investments in automation and industrial digitalization are even more advantageous.

Thanks to the National Industry 4.0 Plan, it is possible to access tax benefits with regard to innovation tax credit (formerly hyper-amortization) and tax credit for Research and Development.