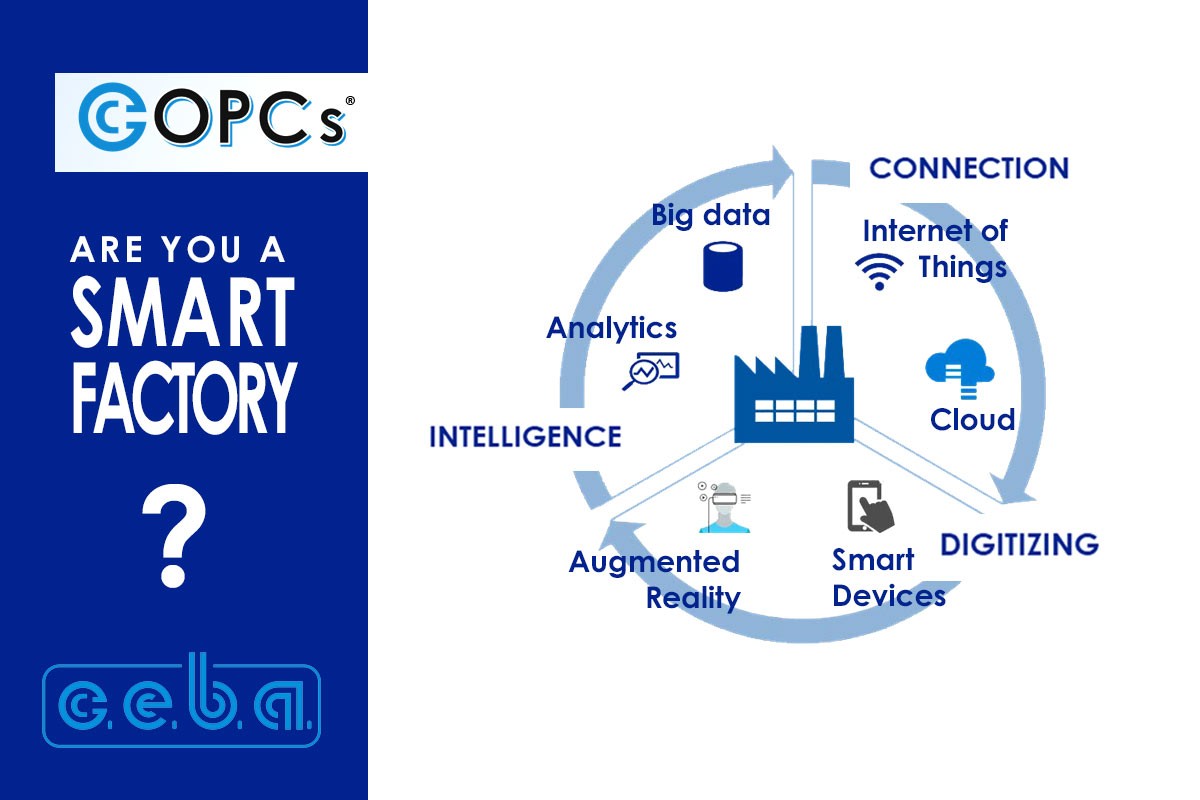

The request we often receive from the market is to have an agile tool able to monitor the company's production and returning easily understandable and analysable data, from which derive useful decisions in a short time for the purpose of optimizing work.

Why has production dropped today? What went wrong? Could we have avoided it? And reduce its incidence? These are all questions that, without proper data collection and analysis, usually remain without answers.

BUT we have an answer: it's called OPCS.

What to do with a company production management software

Our software allows the collection and management of production data in real time, in order to optimize production, reduce waste, respect delivery times and thus obtain a competitive advantage.

The pluses of our OPCS software

OPCS production management software is, unlike most similar products available on the market, fully customizable and flexible. Is it not enough? The price is also really competitive!

How the OPCS software works

The system records the data detected by the machines continuously or at intervals, storing the measured values in a local memory. It allows you to select and view current and past data and, thanks to their export to CSV files, to make a more detailed analysis with other company tools as well.

OPCS is a secure implementation to any management system. It can be installed on any computer with Microsoft Office connected to the company network.

What the OPCS software allows to do

Orders: input and management

Material: polymer consumption and supplier registration

Archives: process data archiving

Energy: energy and production consumption

Printing: printing and generation of labels, QR code, Barcode

Plant login / logout: plant accessibility

OEE: production efficiency indicator

Alarms: frequency and duration of system alarms

Production: production process and data collection

Report: production reporting

Mobile: web app Recipes, remote recipes and production sheets

Tracking: knowing and tracking a product and its production phases

Remote Assistance: remote control and remote assistance

Maintenance: scheduled and preventive maintenance

ERP Interface: interface with the most common management software and relational databases (OPC UA, SQL)

In conclusion, why use OPCS?

The software, thanks to data monitoring and their organized and clear graphic rendering, allows you to:

- Optimize production

- Respect delivery times

- Making quality products verified throughout the entire production process

- Contain costs

- Reduce waste and malfunctions

- Increase turnover and profits

And now?

Contact us!